CERTIFICATION OF ORIGINALITY

This is to certify I am responsible for the work submitted in this project, that the

original work is my own except as specified in the references and

acknowledgements, and that the original work contained herein have not been

undertaken or done by unspecified sources or persons.

Bi Toroid transformer is invented for obtaining efficiency beyond 100%. The

structure of a Bi Toroid transformer is different from a Conventional transformer

because it has one primary coil and two secondary coils. It is designed using two

different cores, material wise and size wise. The secondary core is designed to be

less reluctance than the primary core. This is done by using larger and higher relative

permeability for the secondary core. This will ensure that the secondary core is less

reluctance than the primary core. Thus, the induced EMF will not couple back to the

primary side. This will ensure that secondary coils induced EMF will follow the less

reluctance path. This will boost the efficiency of the transformer past the 100% mark.

1. INTRODUCTION

1.1 Background

Transformer is an electrical device that transfers energy from a device to another

through electromagnetic induction. Electromagnetic induction can cause losses and

make efficiency rate lesser (typical transformer efficiency – 90% to 99%).[1] The

lesser the efficiency more energy lost occurs

|

| Figure 1 Conventional Transformer pulse movements |

When a pulse of input power is delivered to Coil 1 (Primary coil), it creates a

magnetic wave which passes though Coil 2 (Secondary winding) and back to Coil1

again as shown by the blue arrows. This magnetic pulse generates an electrical

output in Coil 2, which flows through the electrical load providing it with the power

which it needs to operate.

The pulse in Coil 2 also generates a magnetic pulse, and unfortunately, it runs in the

opposite direction, opposing the operation of Coil 1 and causing it to have to boost

its input power in order to overcome this backward magnetic flow, apart from losses occurred during the operation. So, this is what makes electrical efficiency of a

conventional transformer will always be less than 100%

|

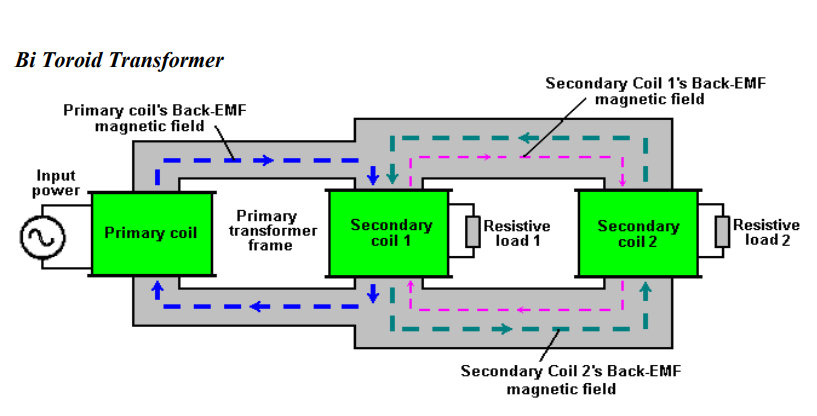

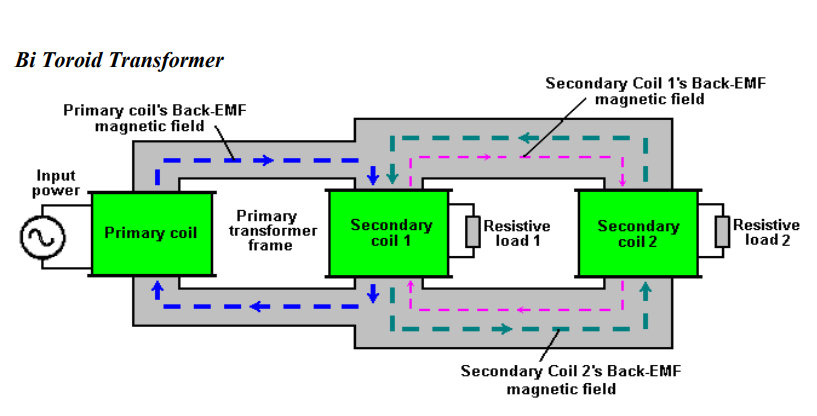

| Figure 2 Bi Toroid Transformer Pulse Movements |

Bi Toroid Transformer is designed and invented by a Canadian Inventor, Mr.

Thane Heins (Patent No: CA2594905A1). It consists of one primary coil and

two secondary coils. Primary core and Secondary core made from different

materials and differs in size. Secondary core is designed to be less reluctant.

So, the return pulse takes a much easier path which does not lead back to Coil

1 at all since secondary coil is made of less reluctant core. This boosts the

efficiency of the transformer. The inventor also claimed that the device has

been able to generate electricity. Thus, the efficiency has go beyond 100%.

1.2 Problem Statement

This device has been patented and claimed to generate electricity because the

efficiency is higher than 100%. If the device is really capable of generating

electricity, it can be used to address energy scarcity problem. However, not much

have been understood and reviewed of the source of the additional energy produced

by the device, I.e. where the extra energy coming from? How it is possible to

achieve the efficiency above 100% and what are the limitations of the device?

1.3 Objectives

- To design, test and analyze a Bi – Toroid transformer using ANSYS software.

- To understand how it works by using ANSYS software

1.4 Scope of Study

- More focus given on the materials used to design the transformer and the

windings.

- Experiments will be carried out to understand how this device work by using

ANSYS software

1.5 Relevance and Feasibility

The study conducted based on transformers, the materials used and the effects of it

on efficiency of the transformer and how to improve it. In addition, the valuation and

the suitable factor to increase the efficiency are done based on past research papers

and experiments conducted.

2. LITERATURE REVIEW

2.1 Conventional Transformer

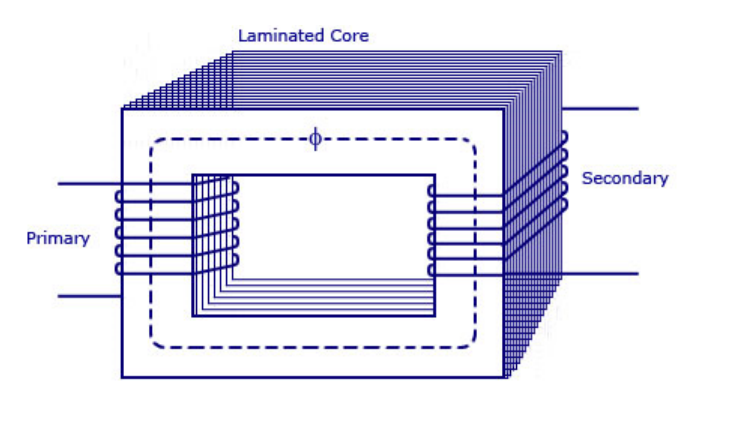

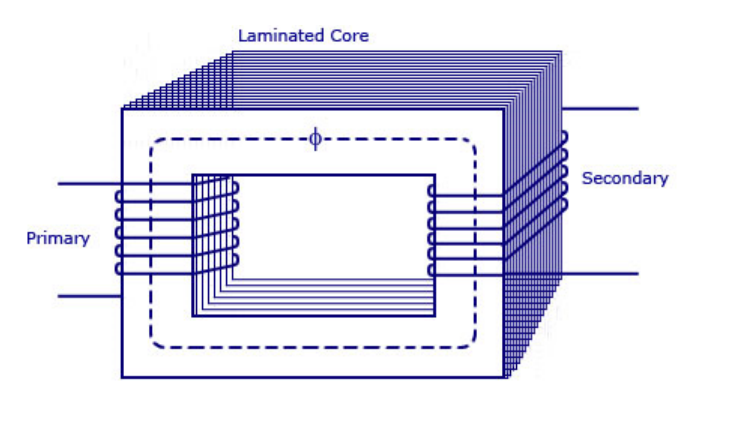

A conventional transformer is a device that has two or more coils of wire physically

wrapped around the laminated core. They consists mainly two cores, primary and

secondary. The primary is connected to an ac power source and the secondary is

open circuited

|

| Figure 3 Conventional Transformer |

Operating Principle: The operating principal of the transformer is based on Faraday‟s Law. There are 2

laws of Faraday, first law states that any changes that happened in a magnetic field of

a coil of wire will cause an electromagnetic field (emf) to be induced in the coil. As

for the second law of Faraday, it is stated that the magnitude of electromagnetic field (emf) induced in the coil is equal to the rate of change of flux that linkages with the

coil.[2] The induced voltage is given by,

{e_{ind}} = N\frac{{d\overline \Phi }}{t} (1)

where Φ¯¯¯¯ is the average flux per turn in a coil and N is is the number of turns in the

coil. Therefore,

\overline \Phi = \frac{\lambda }{N} (2)

where 𝜆 is the flux linkage in the coil across where the voltage is being induced, and

it is the sum of the flux passing through each turn in the coil added. Thus,

\lambda = \sum\limits_{i = 1}^N {{\Phi _i}} (3)

Transformer works using the principle of Faraday‟s law where it uses

electromagnetic induction of two coils, the primary and secondary coils. When there

is a current change occurs in primary side, the secondary side also will have changes

in current. Subsequently, EMF induced in the secondary coil due to Faraday‟s Law

of Electromagnetic induction.[2] Basically, transformers are based on two principles

- Magnetic field (electromagnetism) can be produced by an electric current.

- Voltage induced in the end of the coil (electromagnetic induction) by

changing magnetic field within a coil of wire

So, as a result, the induced voltage in each winding depends on the number of turns

in that winding.

Losses in a conventional transformer that have to be taken into account [3]:

1. Copper / I2R losses are the resistive heating losses in the primary and

secondary windings of the transformer[3].

2. Eddy current losses are the losses due to resistive heating in the core of the

transformer[3].

3. Iron / Hysteresis losses are due to lagging of the magnetic molecules within

the core because of the alternating magnetic flux and it is associated with the

rearrangement of the magnetic domains in the core during each half cycle[3].

4. Leakage fluxes are the fluxes that escape the core and only pass through one

windings of the transformer[3].

The force of power loss in a transformer decides its efficiency. The efficiency of a

transformer is reflected in power (wattage) loss between the primary and secondary

windings. At that point the resulting efficiency of a transformer is equivalent to the

proportion of the power ratio of the secondary winding, to the power input of the

primary winding, and is thus high.

Due to this problem (losses), the efficiency of a transformer is always below 100%,

typical efficiency of a conventional transformer is 91%-99%.[4][1] Efficiency of a

transformer can be calculated as:

{\rm{efficience, \eta = }}\frac{{Output{\rm{ }} power}}{{Input{\rm{ }} power}} (4)

2.2 Bi Toroid Transformer

Bi Toroid Transformer is a special transformer that has developed by a Canadian

Inventor, Thane Heins (patent no: CA2594905A1). It differs with a conventional

transformer in terms of number of coils and number of cores. A Bi Toroid

transformer has on primary coil and two secondary coils whereas a conventional

transformer only has one primary coil and one secondary coil.

|

| Figure 4 Bi Toroid Transformer |

Operating Principle

A Bi Toroid transformer is designed to have one primary side and two secondary

sides. Apart from that, it has two different cores in terms of size and materials. The

secondary core is bigger in size and as for material; it has higher permeability

material than the primary side. This will ensure that the secondary core will have

much lesser reluctance than the primary core, thus, the pulse generated from the core

wont couple back. By doing this, the efficiency will increase dramatically.

|

| Figure 5 Bi Toroid Operating Principle |

A common transformer has an efficiency around (91-99) % depending on the various issues[5]. Apart from that, it only has one primary side and one secondary side. As for a Bi-Toroid transformer, the efficiency can go up to 100% or more and it has one primary coil and two secondary coils. The secondary cores have lower reluctance than the primary core. By doing this, the electromagnetic fields (EMF) will not couple back with the primary core because of the higher reluctance flux path[1]. So, the desired output on no-load will be achieved as same as the input with near no load power factor.[6]

As for the reluctance, it can be adjusted by using different cores or by just using

different sizes for the primary side and the secondary side. The bigger the size, the

lower the reluctance. The other way is to use different cores for primary and

secondary sides. This can be done by using higher reluctance core for example iron

with lower permeability on the primary side and using permalloy which has high

permeability and lower reluctance on the secondary sides.[1][7]

|

| Figure 6: Bi Toroid Transformers |

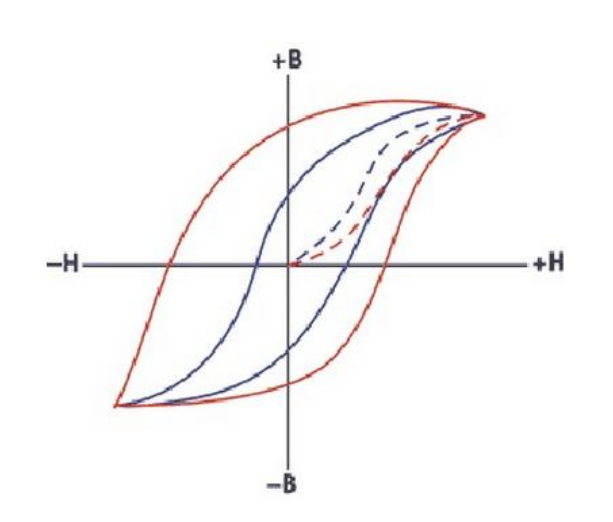

2.3 Materials used for the cores

One of the main criteria in order to design a Bi-Toroid transformer is by using

different materials. Other than using different materials, different sizes of cores can

be applied to design the Bi-Toroid transformers but it would not be as effective as

using different types of materials as the different permeability of the cores will be

more efficient than different sizes of the same cores. [1]

The primary core consist of normal transformer iron core which has permeability

around 200 while the secondary cores consists of permalloy which has permeability

around 100 000[1][7]. Permalloy is made of roughly 80% Nickel and 20% iron so

that makes it reluctance low. [8]. Permeability can be calculated as below,

Permeability(µ) = Flux Density(B) x Magnetizing Force(H) (5)

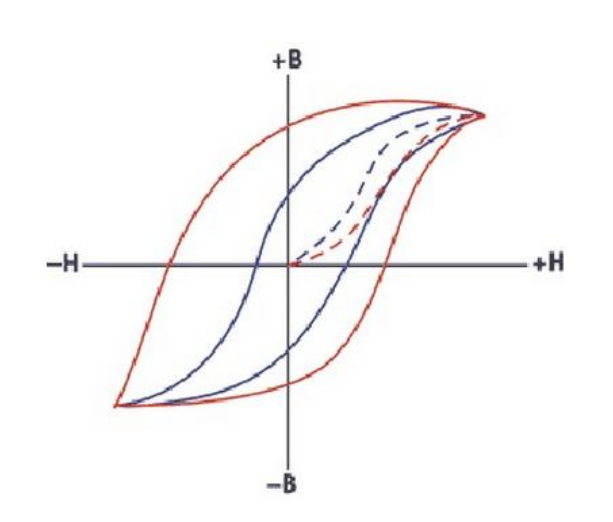

|

| Figure 7: Permeability Graph |

|

| Figure 8: Hysteresis Loop (Iron VS Permalloy) |

Iron has the wider hysteresis loop, that means it has higher reluctance and lower

permeability as for Pemalloy, it has narrower loop, that means it has lower reluctance

and higher permeability.[9]

2.4 Power Factor (PF)

Power factor (pf) is the ratio of the real power (W) and apparent power (VA). The

power factor will be in the range of 0-1. When the power is reactive power (usually

inductive load), the power factor will be „0‟ while, when the power is real power

(resistive load), the power factor will be‟1‟.[10]

𝑷𝑭 = 𝑷(𝐖) / |𝑺(𝐕𝐀)| (7)

PF = Power Factor

P = Real Power (w)

S = Apparent Power (VA)

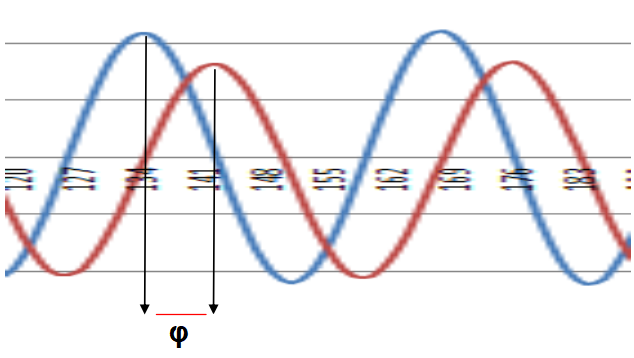

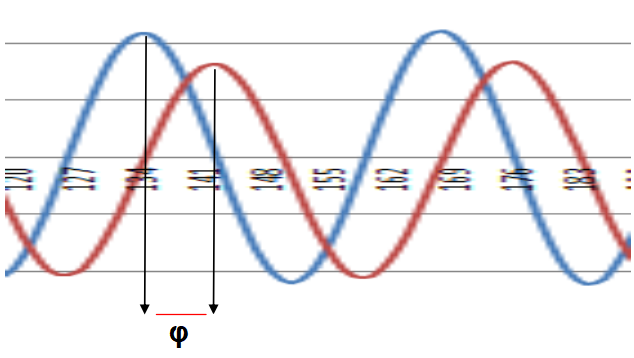

For sinusoidal current, the power factor PF is equal to the absolute value of the

cosine of the apparent power phase angle φ

𝑷𝑭 = 𝐜𝐨𝐬 𝝋 (8)

PF = Power Factor

cos𝜑 = Apparent power phase angle

|

Figure 9 Power Factor Graph

Phase angle φ = 90⁰, so, cos 90 = 0. That means no real power consumed and purely

reactive power consumed. So, this will make the real power = 0.

Figure 10 Power Factor Graph 2

Phase angle φ = 0⁰, so, cos 0 = 1. That means no reactive power consumed and

purely real power consumed.

2.5 Testing/ExperimentsThere are several experiments and testing conducted by Thane Heins in order to

proof that a bi toroid transformer can achieve efficiency above 100%. Below are the

experiment conducted.

Power Factor (pf) testing/experiment

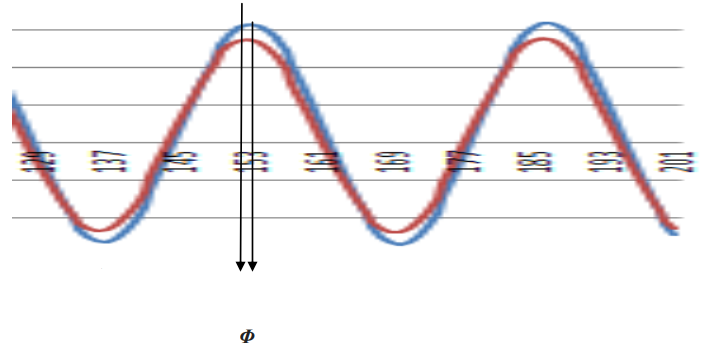

Figure 11: Bi Toroid Sine Waves

Voltage and Current 90 degrees apart, so pf=0 |

Figure 12: Conventional Transformer Sine Waves

Voltage and Curent in phase, so pf=1

The power factor(pf) for Bi-Toroid transformer must be „0‟ or nearly „0‟ since it

consumes reactive power and not real power as a conventional transformer does and

that‟s the reason of the power factor (pf)=1.[11]

Efficiency Test (Conventional Transformer)

Figure 13 Conventional Transformer Efficiency Test

Input Voltage = 9.8 Volts

Input Current = 0.393 Amps

Power Factor = 0.95 / 18 degrees

Load = 10 Ohms

Load Voltage = 5.21 Volts

Load Power = 2.71 Watts

Input Power = 3.66 Watts

Efficiency = 74 %

Efficiency Test (Bi Toroid Transformer)

|

| Figure 14 Bi Toroid Transformer Efficiency Test |

Input Voltage = 122.3 Volts

Input Current = 0.061 Amps

Power Factor = 0.021 / 78 degrees

Load = 10 Ohms

Load Voltage = 5.23 Volts

Load Power = 2.74 Watts

Input

Power = 1.55 Watts

Efficiency = 177 %

3. METHODOLOGY

For this project, more studies will be done on the past research about the Bi-Toroid

transformers. The materials used to design the core and the windings will be the main

edge. Apart from that the experiments and tests involved to determine the efficiency

of the transformer also will be vital

3.1 Tools and Software

ANSYS software will be used to design and simulate the Bi-Toroid transformer.

From the software, the design (prototype) will be analyzed. The main analysis on the

prototype is the efficiency rate of the transformer with the respect of losses. All these

analysis will be conducted using ANSYS software.

3.2 Flow Chart

Figure 15 Flow Chart

At the early stage of the project, studies will be done on the Bi Toroid and the

conventional transformers. The research is conducted to acquire better understanding

on the subject through literature reviews, journals reading, and internet research. The

right materials and windings studied in order to design a Bi Toroid transformer. Once

the transformer is designed with a proper design, the vital part occurs, experiments

and testing. All the required tests and experiments should be carried out in order to

obtain the desired results. All these experiments and results will be obtained by using

ANSYS software. Once the result obtained, the final model for pre sedex should be

done by optimizing the model and a draft report should be completed. The

hardbound submission is the end of the process once dissertation and viva are done.

3.3 No Load Test

Conventional Transformer and Bi Toroid transformer are placed on No Load and the

output observed and the readings will be taken using oscilloscope and multimeters.

Figure 16 No Load Test

3.4 On Load Test

Both the Bi Toroid Transformer and the Conventional Transformer will be placed on

Load and the output observed and reading will be taken.

Figure 17 On Load Test

3.5 Gantt Chart

Table 1 Gantt Chart

|

| Key Milestone |

4. DESIGN OF THE TRANSFORMER CORE (AutoCAD)

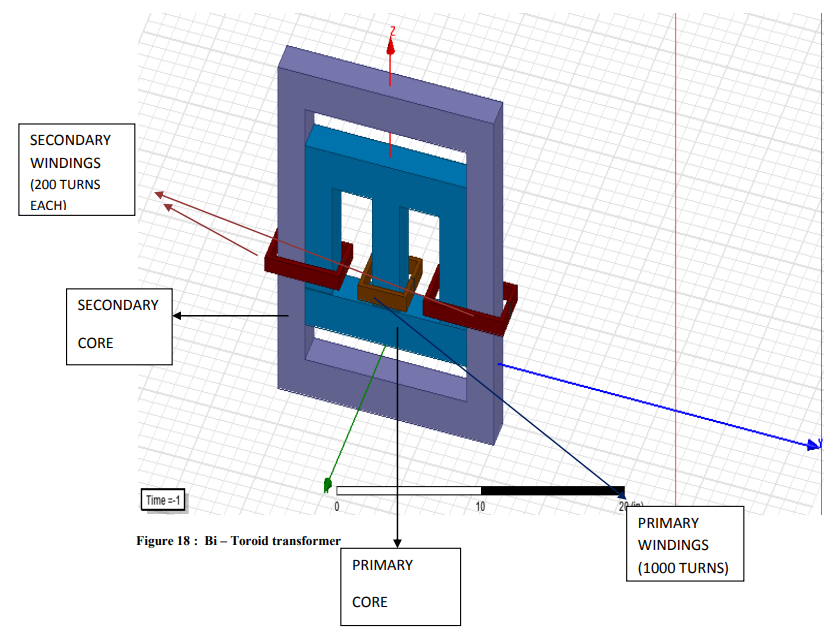

This is the proposed design of the Bi Toroid transformer. It consists of two different

cores with different materials respectively. The primary core is made of silicon steel

whereas the secondary coil is made of permalloy. The size of the secondary core is

twice the size of the primary core; this is due to reluctance, the secondary core is less

reluctant than the primary core.

3D ANSYS SOFTWARE DESIGN

Bi – Toroid Transformer

Conventional Transformer

5. RESULTS AND FINDINGS

BP & BH curves

Figure 20 : BH & BP Curves

Power Factor Testing (Bi-Toroid)

Figure 21 PF graph (Bi-Toroid)

The current and voltage are not in phase, almost 90⁰ apart. So the pf is small, nearly

0. So it consumes reactive power to supply real power.

Power Factor Testing (Conventional)

Figure 22 PF graph (Conventional)

The current and voltage are in phase, so, the pf is nearly 1. It consumes real power to

supply real power.

Efficiency Calculations

Bi Toroid Calculations

|

| Figure 23 PF (Bi - Toroid |

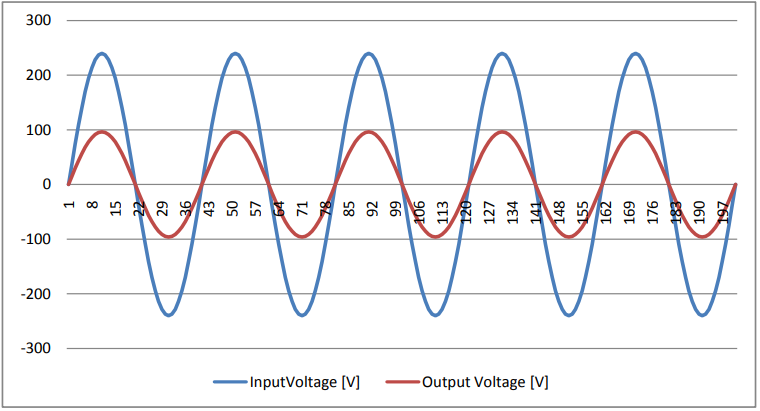

From the above graphs, it shows that the current and voltage for a Bi-Toroid

transformer are almost 90⁰ apart on the primary side. This means:

PF = cos φ

= cos 85⁰

= 0.087

So, the power factor for the Bi-Toroid transformer is nearly "0".

|

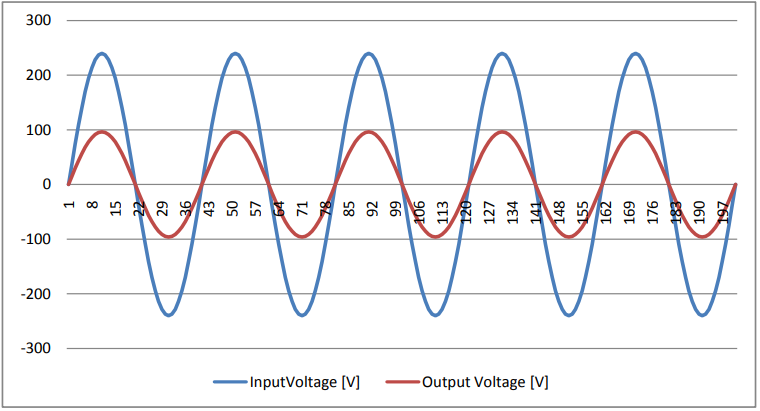

| Figure 24 Voltages ( Bi - Toroid) |

The above graph shows the input/output voltages of the Bi – Toroid transformer. The

input voltage is 240 V while the output voltage is 105 V.

|

| Figure 25 Currents (Bi- Toroid) |

The above graph shows the input/output currents of the Bi – Toroid transformer. The

input current is 0.1 A while the output current is 0.38 A.

Power Calculations

𝑷 = 𝑽𝑷 × 𝑰𝑷 × 𝐜𝐨𝐬 𝝋 (9)

Input Power

P = 240 x 0.1 x 0.087

= 2.088 W

Output Power

P = 105 x 0.3829 x 0.087

= 3.497 W

Efficiency

𝑃 = 3.497

2.088 × 100

= 168 %

Conventional Calculations

From the primary side, the output waveform shows that the current and voltage are in

phase and it‟s almost 0⁰ apart.

PF = cos φ

= cos 15⁰

= 0.96

So, the power factor for the Conventional transformer is nearly „1‟.

|

| Figure 27 Voltages (Conventional) |

The above graph shows the input/output voltages of the Conventional transformer.

The input voltage is 240 V while the output voltage is 96 V.

|

| Figure 28 Currents (Conventional) |

The above graph shows the input/output currents of the Conventional transformer.

The input current is 0.1 A while the output current is 0.25 A.

- Input Power

P = 240 x 0.1 x 0.96

= 23.04 W

- Output Power

P = 96 x 0.2450 x 0.96

= 22.5792 W

Efficiency

𝑃 = 22.5792

23.04 × 100

= 98 %

Calculations (Simplified)

Table 2 Data Gathered:

Table above is the simplified version of the parameters obtained via ANSYS

software. The input voltages and the input current injected for both the transformers

are the same, 240 V and 0.1 A respectively. The output voltage acquired for

Conventional transformer is 96 V while the output voltage obtained for Bi-Toroid

transformer is 105 V. As for current, Conventional transformer showed output

current of 0.245 A while the Bi-Toroid transformer showed 0.3826 A. Both

transformers obtained less core losses, 560mW and 750mW respectively.

Table 3 Power & Efficiency

Table above shows the efficiency rate of both Conventional transformer and Bi –

Toroid transformer. Efficiency rate for the conventional transformer is 98% while the

efficiency rate for the Bi – Toroid transformer is 168%. It proves that Bi – Toroid

transformer can achieve efficiency beyond 100%.

5. CONCLUSION AND RECOMMENDATION

As a conclusion, a proper study regarding a Bi Toroid transformer should be carefully conducted because the Bi-Toroid transformer can achieve its 100% or more efficiency if the correct methods followed. The choosing of the materials depending on its permeability and reluctance, the different sizes of the cores, secondary core must be larger than the primary core, as well as the number of turns involved in primary side and two secondary coils are vital in order to achieve the desired objectives.

Permalloy used as the material for the secondary core. It is chosen because of its high

permeability and very low reluctance properties. Since, there are less availability of

this materials possibly due to its usage, it is hard to conduct a proper research or

studies in this materials in person. So, it is recommended that different materials like

this would be made available for students to enhance or develop something new.

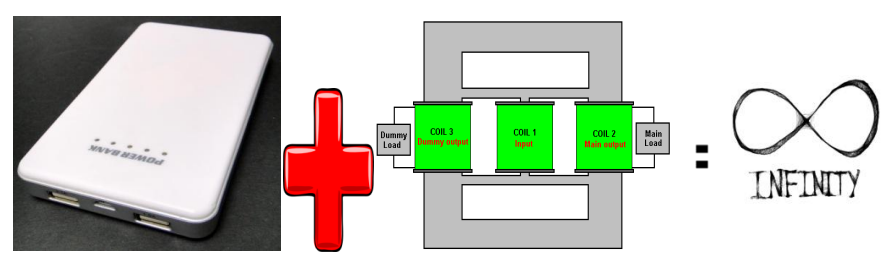

Apart from that, in this modern world, technologies are developing to be on par with

the living standards that improving from time to time. Portable electronics product

plays a vital part in today‟s generation such as mobile phones, cameras and ipads.

Sadly, all these products use a rechargeable battery that means, it will drain out of

charges with use. The more you use, the faster it will run out of power[12].

In order to counter this problem, portable power bank discovered. It can charge a

device up to four times depending on the size of the battery. But, there is a minus

point with portable power bank. It will supply power according to its size that means

it has limitations. A 7500mAh power bank can supply up to its maximum capacity

which is 7500mAh only and have to be recharged in order to perform again.

A Bi Toroid transformer can be used in developing a power bank. Since its efficiency

is more than 100%, it just needed to be charged once. The transformer will supply

extra voltage and the extra voltage can be used to automatically recharge the power

bank without being recharged manually. It can be used forever without being worried

about the capacity of the power bank.

|

| Figure 29 Application of Bi Toroid Transformer |

The studies and research conducted above are one of the preliminary assessments.

The design and modeling in ANSYS is just to prove that the Bi – Toroid transformer

can achieve the objective which is to obtain efficiency beyond 100 %. Hence can

harvest its own energy. This is not possible without the prototype. So, the prototype

must be fabricated to make sure the theoretical results obtained through simulation

are no fluke.

Revealed At Last: Ancient Invention Generates Energy-On-Demand

✔ Nikola Tesla’s method of magnifying electric power by neutralizing the magnetic counter-forces in an electric generator

✔ Combination of induction motor and alternator

✔ Combine generators with induction motors - self-powered generators with rotary motion

✔ Various methods of generating high power immobile generators

✔ Or maybe called Overunity for the system. Mother Nature doesn't care about people calling or naming phenomena. Overunity or Free Energy, or Zero Point Energy (ZPE) are just a few different wordsAlso See: Ether Technology

.png)